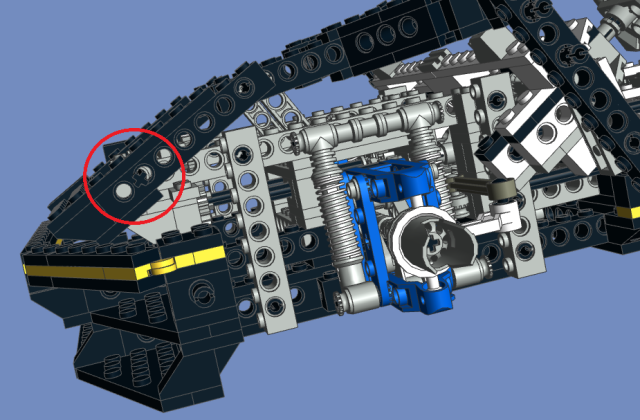

Sometimes due to the nature of plastic parts, when a real life model is translated into a computer model there may be some discrepencies in part fit up. This is especially true of Technic models where the complicated angles can lead to shortfalls/excesses of 4-5 ldu. While I'm willing to live with a difference of fractions of an ldu up to 1-2 ldu, when I hit the 4-5 range I become dissatisfied. I'm just curious how other authors deal with gaps or overlap in parts when building models.

Gaps/overlap in part fit up

RE: Gaps/overlap in part fit up

2019-03-22, 7:58 (This post was last modified: 2019-03-22, 18:08 by Philippe Hurbain.)

2019-03-22, 7:58 (This post was last modified: 2019-03-22, 18:08 by Philippe Hurbain.)

Quote:I'm just curious how other authors deal with gaps or overlap in parts when building models.Yeah, models that rely - even a little bit - on parts flexibility or play in joints are a nightmare to model. Modern models are less prone to that, but it does happen in older ones (here I mostly speak about Technic models). When this happens, I first check what I have modeled so far (might be a mistake somewhere), and if I find nothing I try to minimize visual impact by distributing the error over many joints.

(2019-03-21, 22:44)Orion Pobursky Wrote: Sometimes due to the nature of plastic parts, when a real life model is translated into a computer model there may be some discrepencies in part fit up. This is especially true of Technic models where the complicated angles can lead to shortfalls/excesses of 4-5 ldu. While I'm willing to live with a difference of fractions of an ldu up to 1-2 ldu, when I hit the 4-5 range I become dissatisfied. I'm just curious how other authors deal with gaps or overlap in parts when building models.Hi Orion

I do it just like Philo.

A big problem will be split as well as possible.

A friend of mine likes to use these tolerances on his MOCS.

Since I was often desperate to present it in the instructions accordingly.

Johann

If nothing goes right, go left.

(2019-03-22, 7:58)Philippe Hurbain Wrote: When this happens, I first check what I have modeled so far (might be a mistake somewhere), and if I find nothing I try to minimize visual impact by distributing the error over many joints.

Same on my side. I remember that I build 850 twice and then with real bricks and a third time digitally and found out, that TLG used the created 'stress' on the beams to bring some friction to the fork mechanism. Anyway I never finished the digital model. As I have no idea how to do it. :-)

/Max

RE: Gaps/overlap in part fit up

2020-03-07, 20:27 (This post was last modified: 2020-03-07, 20:36 by Marc Giraudet. Edit Reason: Size of bricks )

2020-03-07, 20:27 (This post was last modified: 2020-03-07, 20:36 by Marc Giraudet. Edit Reason: Size of bricks )

(2019-03-22, 21:54)Max Martin Richter Wrote: Same on my side. I remember that I build 850 twice and then with real bricks and a third time digitally and found out, that TLG used the created 'stress' on the beams to bring some friction to the fork mechanism. Anyway I never finished the digital model. As I have no idea how to do it. :-)

/Max

As I built the 8416 set (the best Technic Forklift set IMHO) I took time to review the old 850.

The file uploaded in OMR have a wrong gear soluce (1 axle missing) so I totally rebuilt it.

850 - Fork lift truck.mpd (Size: 10.92 KB / Downloads: 2)

850 - Fork lift truck.mpd (Size: 10.92 KB / Downloads: 2)

File OMR compliant

Known errror : 6 bricks 2x2 "resized" for matching purpose.

Note : There are two version of the notice. This model is compliant with 120055 (with an extra row of plate under the seat).

(2020-03-07, 20:27)Marc Giraudet Wrote: As I built the 8416 set (the best Technic Forklift set IMHO) I took time to review the old 850.

The file uploaded in OMR have a wrong gear soluce (1 axle missing) so I totally rebuilt it.

File OMR compliant

Known errror : 6 brick 4x4 "resized" for matching purpose.

Note : There are two version of the notice. This model is compliant with 120055 (with an extra row of plate under the seat).

I think I mentioned this in the Technic thread, I solved the same issue by making a version of the 2x2 brick that is 1 LDU too short, then I swapped that in for 4 of the 7 bricks in the stack. This compensated for the 4 LDU offset of the axle holes at the top of the lift mechanism, and was easier to compute than distributing the error equally across all 7 bricks.

Similarly, in my version of the 8865 Test Car, I very slightly scaled the matrix for one of the angled beams in the roof structure, to make it fit the joints on each end.

« Next Oldest | Next Newest »

Users browsing this thread: 1 Guest(s)