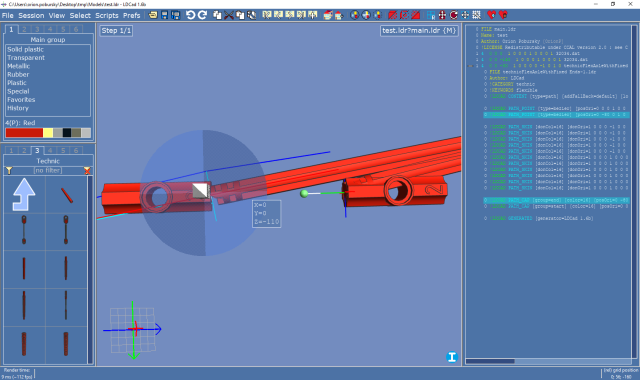

I'm getting an odd error when I edit my custom flex axle in a certain way. Attached is a test case file.

Step to reproduce:

- Open test.ldr

- Enter nested mode

- Click on either control point

- Hit Ctrl-R to enter rotation

- Enter an arbitrary number into the rotation field

- Hit accept and notice odd output

Step to reproduce:

- Open test.ldr

- Enter nested mode

- Click on either control point

- Hit Ctrl-R to enter rotation

- Enter an arbitrary number into the rotation field

- Hit accept and notice odd output